Restricted area system for mine site safety

![]()

With numerous dangerous or hazardous elements on a mine site, it is important for personnel to be able to recognise where these dangers are located. Confined spaces, the use of explosives and heavy equipment use are all examples of potential dangerous situations that need to be monitored so as to ensure the continued safety of employees.

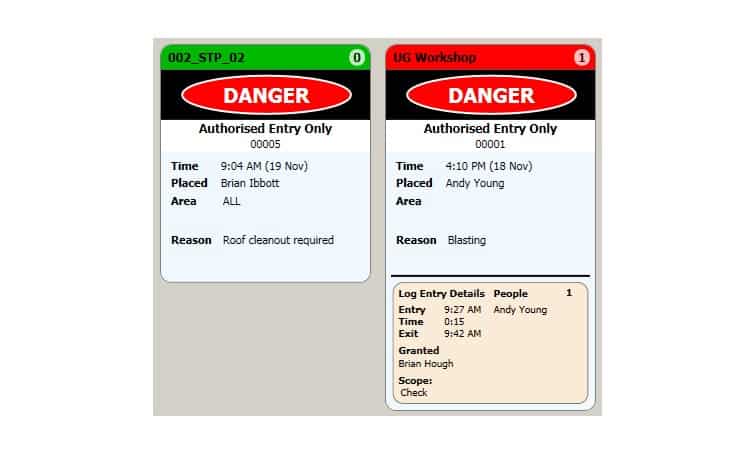

MICROMINE’s fleet management and mine control solution, Pitram provides restricted area system monitoring capability via the controlled areas module to monitor access to hazardous or restricted areas. The module provides the tools needed to manage a site’s signs and permits requirements by tracking personnel working in those areas.

Controls for hazardous areas

When the areas have been established, supervisors are able to determine the controls set for each area. Controls monitored can include the maximum number of personnel allowed in an area, the maximum duration permitted within the area or if any special personal protective equipment (PPE) is required.

When personnel enter a hazardous area, the restricted area system will monitor their activity and notify the control room if they have exceeded the maximum duration or personnel limit within the area. This allows the control room to alert staff to a potentially harmful situation and prevent something from happening.

Remote access

Pitram’s restricted area system capabilities are also able to monitor personnel working off-site, in areas where radio coverage is poor and where regular contact is required.

Choosing Pitram

The benefit of implementing a restricted area system like Pitram’s controlled areas module is the increased control provided by the management of the restricted areas. Increased control allows mining operations to improve the safety of their site and ensure their employees are safe from harm at all times.

Further reading

>Learn more about Pitram’s restricted area system.